As a Tag Heuer Authorised Workshop we have been assessed to meet the standards required for on-site Tag Heuer repairs, covering the full range of interventions up to full servicing and repair. In this instance we’re taking care of a Tag Heuer Monaco watch, with a black dial, sub-dial seconds and a date indicator at 3 o’clock.

This watch was not working on arrival and the case was very scratched and beaten up. Initial inspection of the movement found it in dire need of a service, as the oils and greases designed to keep everything working properly were mostly dried up.

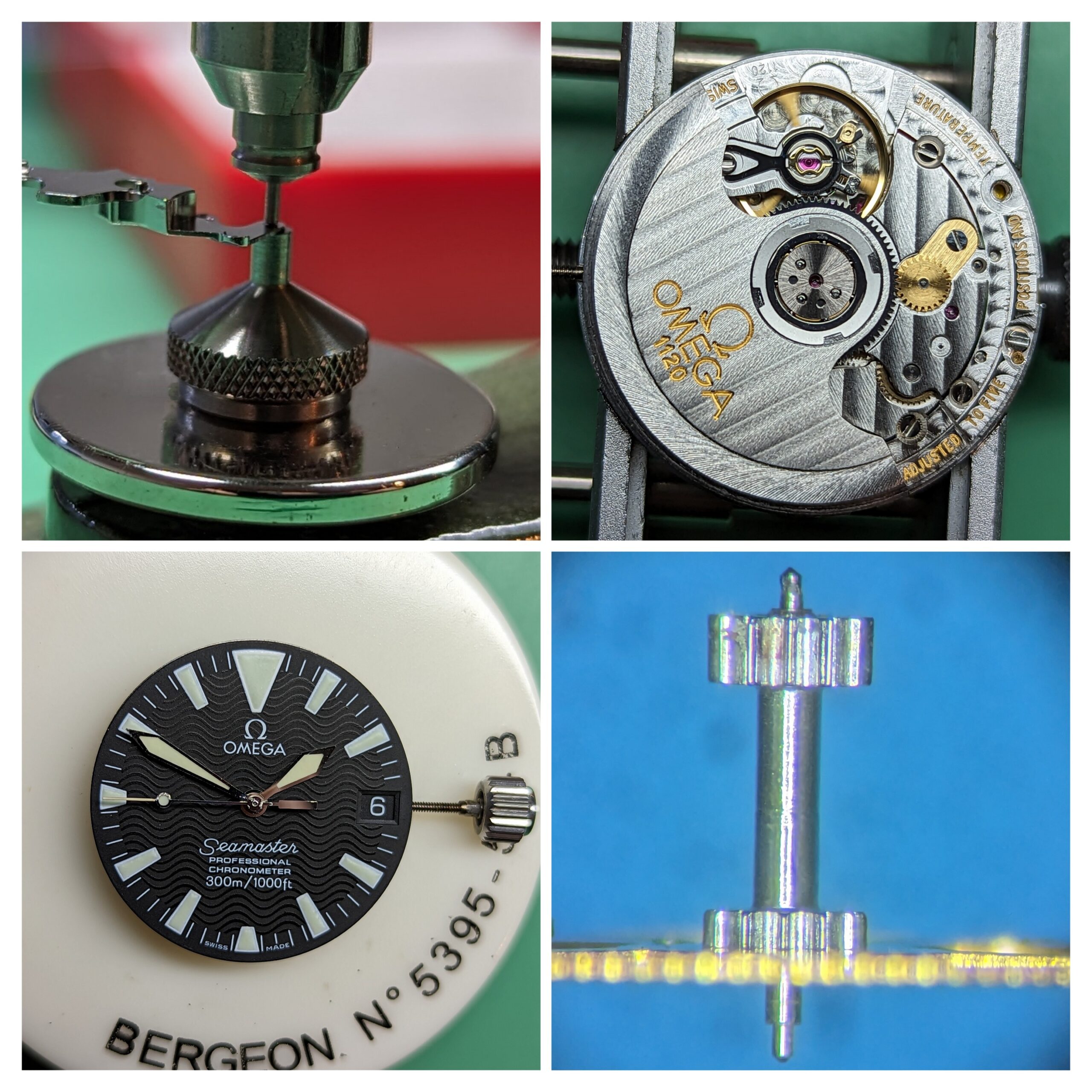

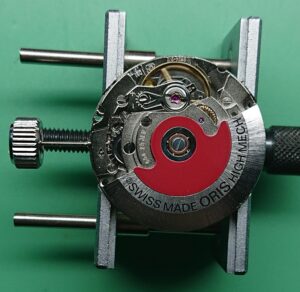

The fault stopping the watch from working turned out to be a broken mainspring – the source of power for the movement. The movement powering this watch is a Tag Heuer Calibre 6, which is based on the ETA calibre 2895-2. To repair this watch we needed to give it a full service and fit a new mainspring. We also replaced the worn reversing wheel, part of the automatic winding mechanism. Alongside the necessary remedial works to the movement, our client requested work to improve the aesthetic condition.

To clean and polish the case it is completely disassembled before we refinish each element using a variable speed polishing machine with a selection of different polishing mops and compounds. We use certain wheels to maintain the flat lines of the case. When polishing it’s often a case of “less is more” as anything which may compromise the original profile of the case is undesirable.

While it was not necessary to order case parts in this instance, As a Tag Heuer Authorised Workshop, we are able to order and additional parts we may have needed to conduct a comprehensive repair of this watch. Parts we are able to obtain include bezels, crowns, glasses, pushers and seals. Only authorised workshops can order these parts for Tag Heuer watches.

After a full service this Tag Heuer Monaco watch is back to excellent working order. The refinishing works to the case have restored the aesthetic condition to an excellent standard too. Another job well done!

Yours sincerely

David Clark FGA DGA MJVA PJDip. PJGemDip.

Managing Director, JVA Registered Valuer®

W.E. Clark & Son Limited