We are skilled in the repair and restoration of a whole range of different types of watch – both modern and vintage. One group of watches we regularly work on are military watches. Military watches are watches which, as the name suggests, have been issued to members of the armed forces at some point.

Probably the most famous sub-group of military watches is the “Dirty Dozen”. In the 1940s, the MOD needed watches produced to a certain specification for issue to the armed forces. Twelve manufacturers were eventually approved to produce these watches – hence the name, the Dirty Dozen. In alphabetical order, these makers were: Buren, Cyma, Eterna, Grana, Jaeger Le Coultre, Lemania, Longines, IWC, Omega, Record, Timor and Vertex. As you may note, all these makers are Swiss. Unfortunately British watchmaking had been in decline for some time, so lacked the required means of production to make such timepieces.

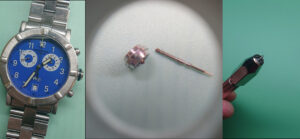

The military watch we’ve been working on here is later than the “Dirty Dozen”, though it’s still from the period before the MOD switched to issuing quartz watches (which was just after the Falklands War). Indeed this CWC W-10 was one of the last general purpose mechanical watches issued to the military in the UK.

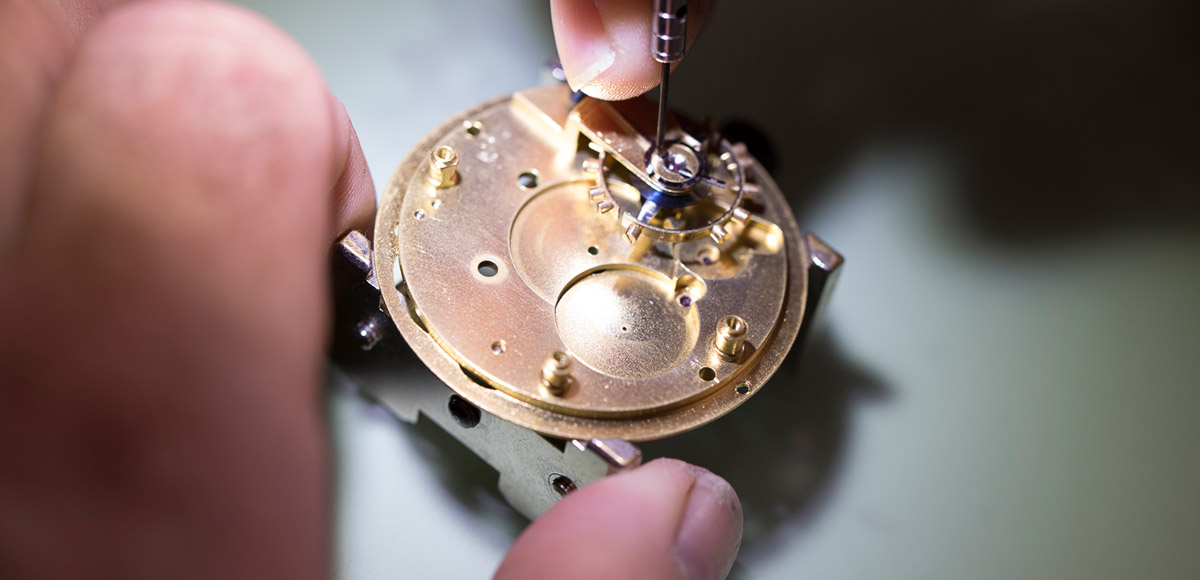

On arrival with us it was running though not keeping time. Inspection of the movement revealed it had likely not been serviced for many years, so a full service and new mainspring was required.

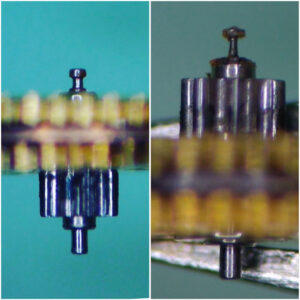

The movement used in this watch is an ETA 2750 manual wind mechanical movement. This is a good, robust movement, with a hacking function to stop the second hand when the crown is pulled out into hand-setting position. During a full service the movement is completely stripped down, cleaned, reassembled, oiled, adjusted and tested.

Our client stressed the need to keep everything original, so the armoured plexi-glass dome was left “as is”, likewise with the one piece steel case. In many instances originality is of great importance and we are only too happy to oblige. We can also offer our advice on what is best for the specific watch in question if our client is unsure. Once the watch is fully cased up it’s ready to go on test before returning to our client.

Yours sincerely

David Clark PJDip PJGemDip CertGA

Managing Director