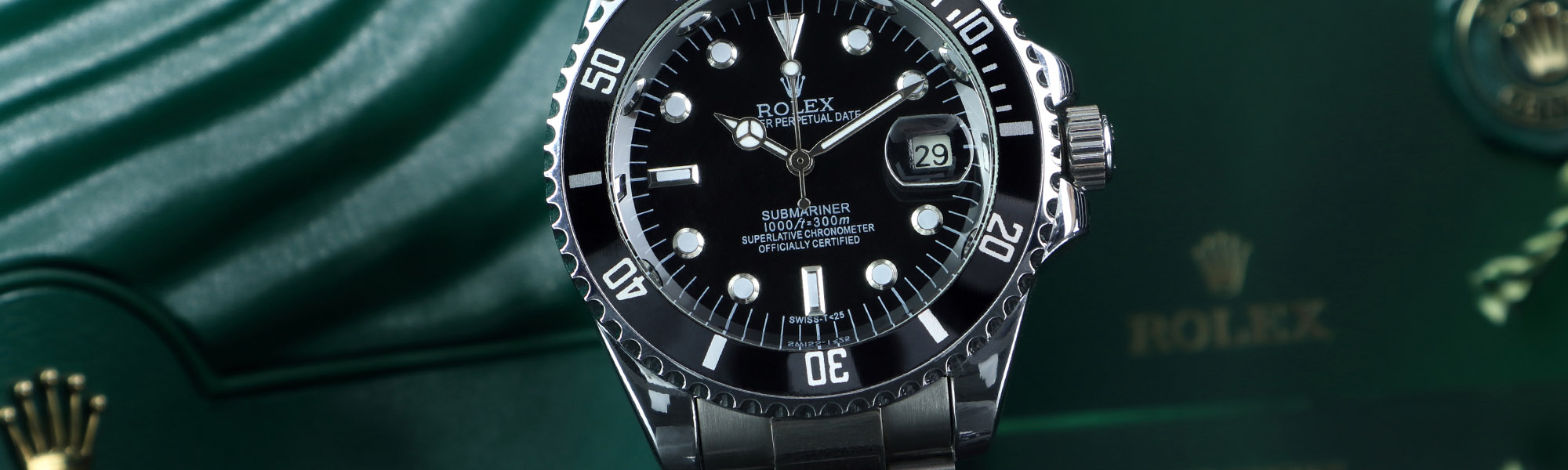

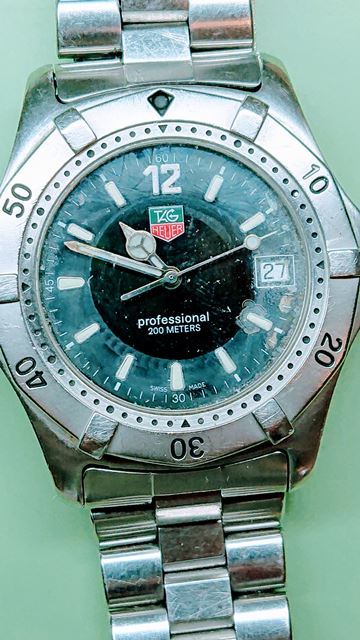

Our fully equipped on-site watch workshop offers a full range of repairs – from smaller jobs like battery changes and glass replacements through to full servicing of the vast majority of brands

including Omega, Tag Heuer, Longines, Breitling and Rolex.

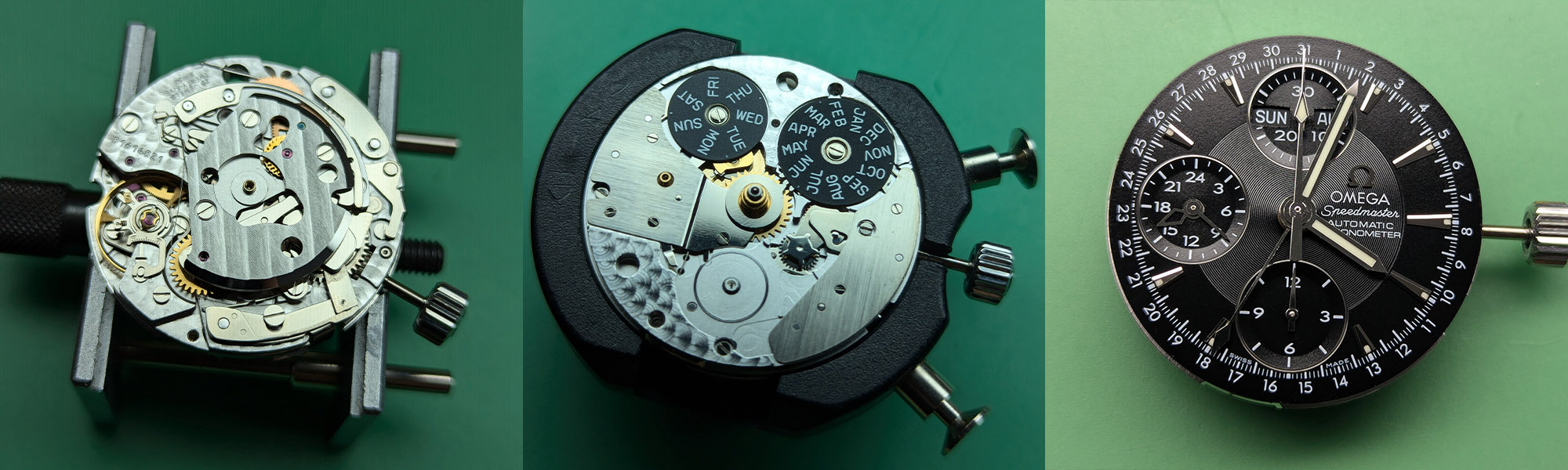

For this job we are working on an Omega Speedmaster. This is not a conventional Speedmaster however, as alongside the chronograph complication we have a triple calendar indicating the day,

date and month, as well as a 24 hour indicator. That gives the dial a grand total of 8 hands and two additional indicators. This watch was working on arrival though losing time when put on a

timegrapher.

“Servicing intricate watches like the Omega Speedmaster ensures every detail, from the mainspring to the chronograph, is meticulously restored for peak performance and enduring reliability.”

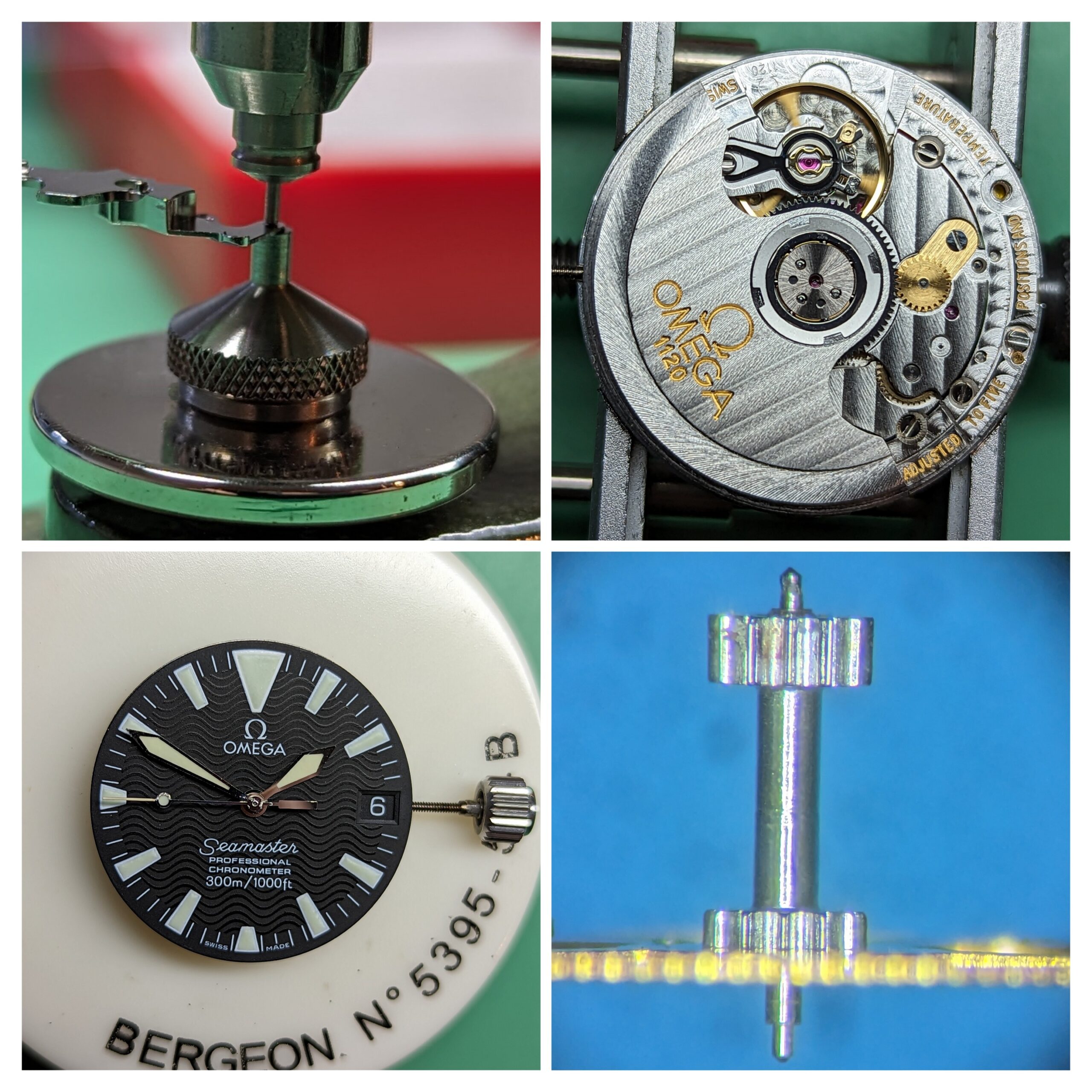

First we disassemble the movement. This Omega Speedmaster uses an Omega calibre 3606A. This is a chronometer rated version of the ETA calibre 7751. No major faults are found, just the usual

signs of deterioration of the old oils and greases. With a movement like this with multiple functions there are many more parts than a conventional “three hand” movement indicating time only. That means there’s lots more to disassemble and check.

Once fully disassembled the movement is cleaned – first going through a manual cleaning process before a cycle in our Elma Solvex RM automatic cleaning machine. When parts are completely

clean and dried, we can commence reassembly. We follow the manufacturers technical guidelines for the correct usage and placement of oil and grease, as well as the use of other treatments such as epilame.

As part of the service we fit a new mainspring and a new reversing wheel. We always endeavour to fit a new mainspring as part of a service, though it's especially important when dealing with a watch like this. The mainspring is housed inside a barrel which is buried in the very depths of the movement underneath all of the chronograph mechanism, so replacing it is not straightforward without the watch being fully stripped down.

Alongside the movement servicing we give the case and bracelet thorough a clean and fit replacement seals as appropriate before conducting a pressure test to confirm water resistance. We

can now reunite all elements of the watch. With the movement refitted and everything checked on the timing machine, we can close the case back before a final pressure test.

With the works completed we now test the watch using an Elma Cyclomotion watch winding machine, as well as testing in static positions and for the correct functioning of all features

including the chronograph and quick change of the day and date/month. After the testing period is complete this fantastic Triple Calendar Omega Speedmaster Chronograph can be reunited with our client.

Summary:

Our on-site watch workshop specialises in expert repairs and servicing for luxury timepieces, including complex models like this Triple Calendar Omega Speedmaster Chronograph. Through meticulous disassembly, cleaning, and reassembly, we follow the highest standards to restore precision and functionality. Key elements, such as the mainspring and reversing wheel, were replaced, and the case and bracelet were cleaned and resealed for water resistance. After rigorous testing, this remarkable timepiece was returned to our client in optimal working condition. Whether your watch requires minor adjustments or intricate servicing, our skilled team ensures exceptional care at every stage.

Looking to have your Designer Watch Serviced and repaired?

Try our Royal Mail Special Delivery FREEPOST service, all watches are fully insured for up to £20,000 throughout their postal journey from the moment the package leaves your hand to when it is received by you. Book yours in now!